In a previous article, we covered the basics of a standard boiler layup. But that’s not all there is to it. There are also other things you need to know, such as specific procedures that only apply to one kind of boiler layup and not the other. And we’ll be covering all of this in part two of our boiler layup guide.

For Dry Layup Only: Closing Up the Boiler

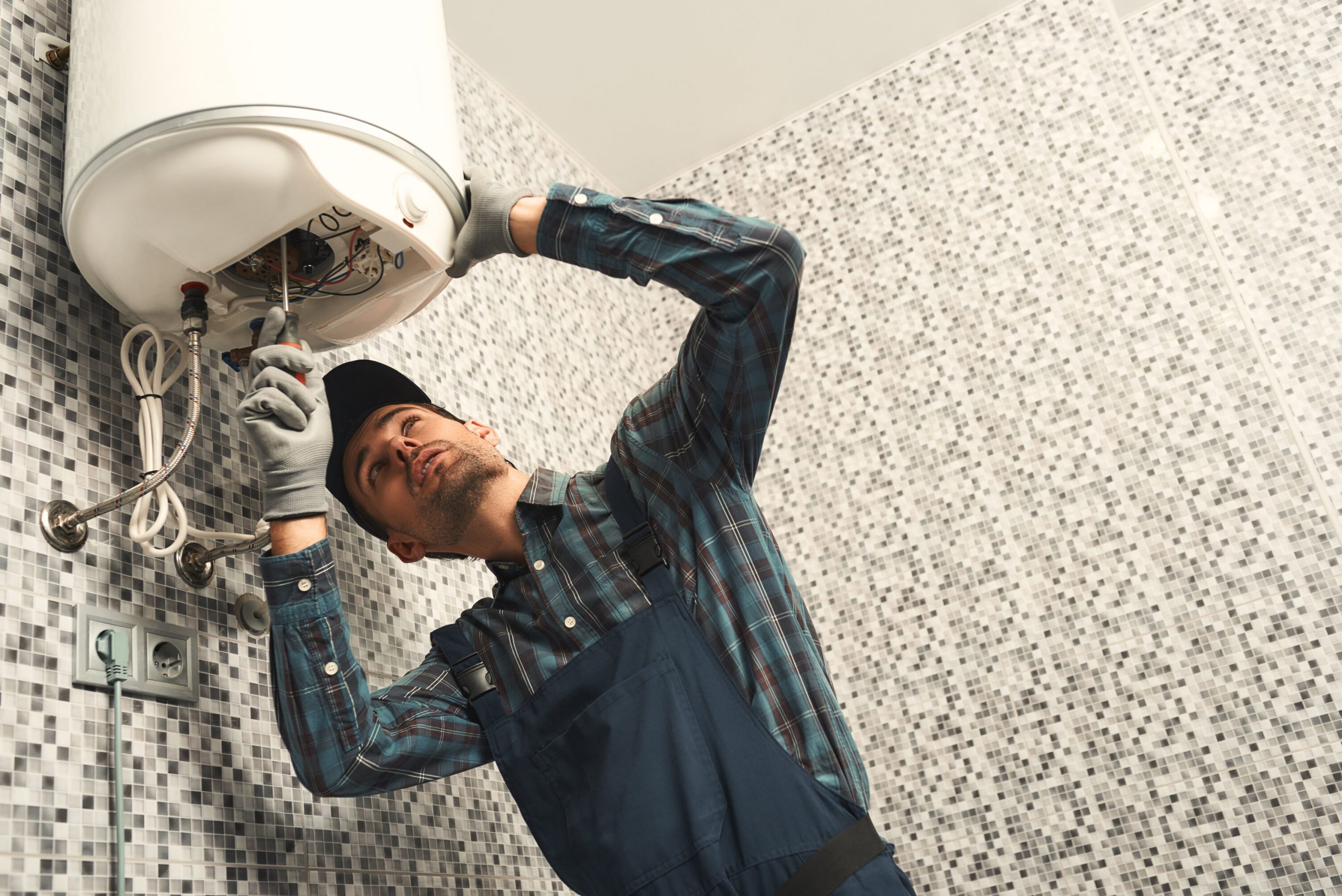

After examining the internal and external components, the next thing you need to do is to close up the boiler if you’re only doing a dry layup. This means that you’re not going to add in any additional components. This is also the case if you’re using an existing boiler and are only out doing repairs.

If you’re not using a pattern, then you’re going to need to mark on the inside of your boiler where the ports are. But if you do use a pattern, then you should attach it to the inside and drill your ports in the right spots.

After marking and drilling, you need to fill in any holes that you didn’t get with epoxy. The epoxy should be about the same consistency as toothpaste. The best way to ensure a good spread is to use a small tool with a rough edge. This makes sure that the epoxy gets into every nook and cranny.

Once again, you need to avoid dripping epoxy because this is a common mistake that can easily lead to air bubbles. Air bubbles don’t play well with heat, and they can cause the epoxy to crack.

For Wet Layup Only: Adding Chemically Treated Water

If you’re doing a wet layup as opposed to a dry layup, you’ll need to fill the boiler with chemically treated water. This will prevent any oxidation or rust from taking place. It also helps to prevent any mould from growing.

A good rule of thumb is to fill the boiler with about an inch of water. The water should be treated with an acid neutralizer, which will prevent rust from forming. This is especially important if you’re going to be leaving the boiler out in the open.

Once the boiler is filled, you’ll need to make sure that the pressure valve is open and close the door. You’ll also want to put some water in the firebox.

Once you’ve done that, you’ll need to test the pressure release valves. This is to make sure that you have a good seal and that the boiler will be able to withstand external forces. After doing that, you need to turn the boiler off and leave it to dry on the ground.

Final Thoughts

While laying up a boiler may seem like a simple task, it’s actually a very detailed and meticulous one that requires a lot of care and attention to detail. If you’re having problems with your boiler or need to repair or replace it, then it’s a good idea to get in touch with a boiler repair company to help you out.

Find the right boiler for your needs with the help of London Climate Hire. We provide boiler hire services in London. Our fleet of commercial boilers and heaters has been selected through our years of experience in this industry, these are tried and tested applications, and we’re confident in saying that they are the most efficient equipment in the industry, designed and fully packaged to deal with the rigours of hire. Get in touch with us today!