An HVAC system has several key parts and requires regular maintenance. Aside from that, it’s important to take good care of it and ensure it doesn’t overheat. A good way to do this is by renting a chiller meant for that very purpose.

As a general definition, a chiller is used to remove heat from a liquid by way of absorption refrigeration or vapour-compression cycle. When you rent a water-cooled chiller, their efficiency goes beyond that of air-cooled coolers.

The Chiller

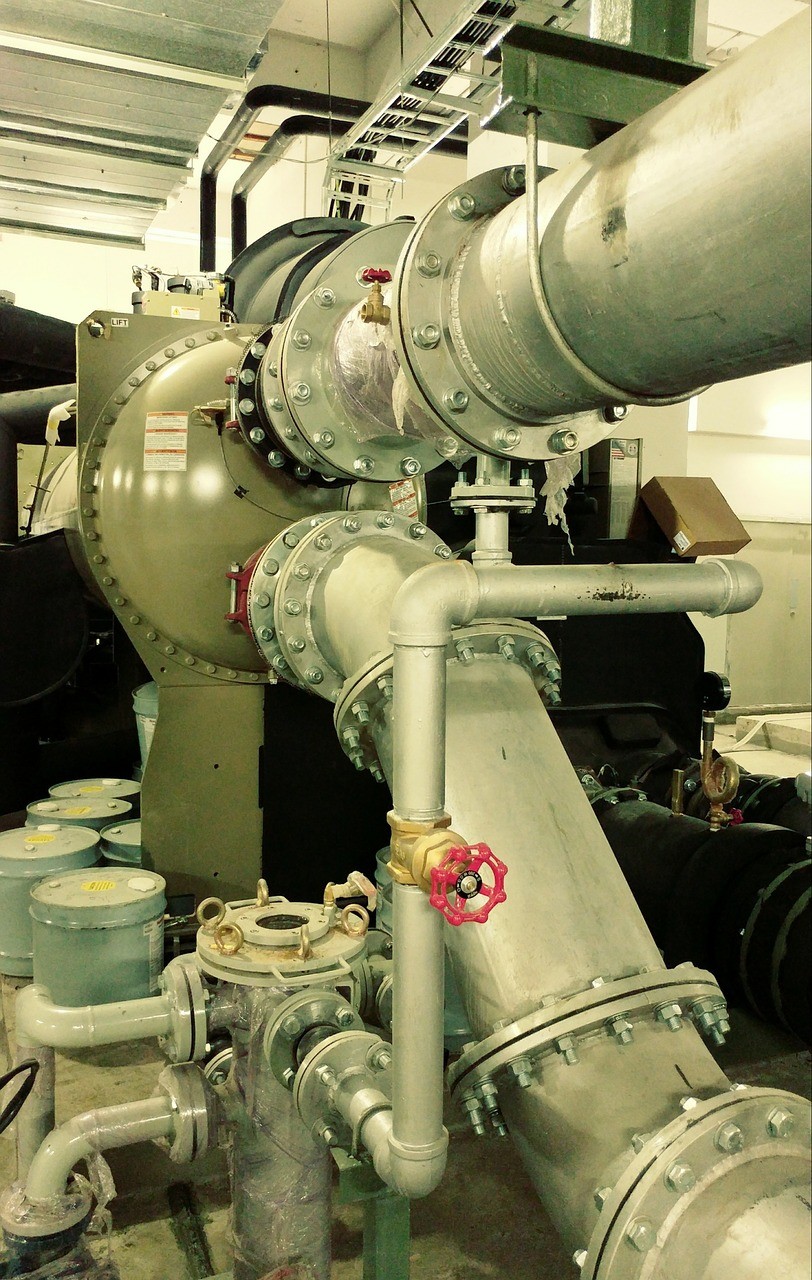

As a whole, a chiller has seven main parts, namely:

- Compressor

- Condenser

- Control units

- Evaporator

- Expansion valve

- Power panel

- Water box

While there are portable versions, the space for installation must be predetermined first. It should also be explicitly stated whether the rental is for the water cooler or the one with air.

Get a Water-Cooled Chiller

One of the biggest benefits of a water-cooled chiller involves operations being much quieter. When businesses have cooling needs, whether on a large scale or a smaller one, water-cooled chillers are absolutely the most suitable. Most of all, when facilities have a space limit, they can still be used. There are also portable means available.

Making use of a chiller is great for temperature control in a home or an organisation. It’s a confined rental solution that keeps the overall working and living environment both productive and comfortable.

Industrial Chillers

There are a number of processes that are generated during production. Heat from burning, equipment or friction is inevitable. This is why process cooling is utilised by industrial chillers so that all the hot air and general heatwaves get redirected elsewhere, not at the equipment. The heat is removed by the cool fluid directed by the pumping system from the chiller to whatever process is ongoing. Since the process water is what’s eliminating the heat, equipment remains cool throughout.

In this way, component lifespans as a whole get an extension. More importantly, production doesn’t stop or get bogged down by unnecessary issues.

There are four key components to industrial chillers:

- Evaporator – This is the first step in the cooling phase. Heat boils the refrigerant until it’s a low-pressure gas coming from a liquid.

- Compressor – This converts gas to high-pressure prior to its heat being released in the condenser.

- Condenser – Condenser water, sometimes known as ambient air, then cools the gas back to a liquid that’s low-pressure and low-temperature.

- Expansion valve – Liquid refrigerant ends up in the expansion valve in order to return to the evaporator. With this, the cycle starts all over again.

It should be noted that process chillers are not the same as standard HVAC systems found in either offices or homes.

Conclusion

Renting a chiller to support HVAC systems during events and such is crucial. It helps the component’s overall lifespan and performance. More importantly, it prevents the likelihood of an overheating device or system considerably. Take note that there’s a difference between standard HVAC systems and process chillers. The latter is ideal for helping production run smoothly.

Looking for a chiller rental worth your money? Check out London Climate Hire today! We have rental solutions for chillers, boilers, generators and more. As HVAC specialists, we’re open to serving clients in London, Sussex, Hertfordshire, Buckinghamshire, Kent, Surrey and Berkshire.